Fiberglass Versus Aluminum

Trailers

READ THIS BEFORE

YOU BUY AN ALUMINUM TRAILER

We adventure in the rugged deserts of Utah and we set out to build a beautiful teardrop trailer that can handle it generation after generation. Historically, fiberglass trailers have lasted longer, retained their value better and, more importantly, eliminated a seam at the roofline. We have aluminum and fiberglass capability, but fiberglass is better for Bean and that is why it is proudly featured.

Follow our Q&A below outlining these differences.

Aluminum or Fiberglass Q&A

Aluminum or fiberglass, which one is better for a teardrop trailer?

Fiberglass is better than aluminum in every major attribute relevant to building a durable teardrop trailer.

What makes you qualified to determine which material is better for a teardrop?

We have been fabricating in aluminum for more than 18 years and fabricate 3 times as many aluminum products as we do fiberglass products (see our associate company sterlingatm.com). If aluminum were a better material for a trailer, it would be easier and cheaper for us to build Bean Trailer that way. We believe in using the right material for the right application and that material is fiberglass for Bean.

Are you comparing cheap RV fiberglass siding to sheets of aluminum?

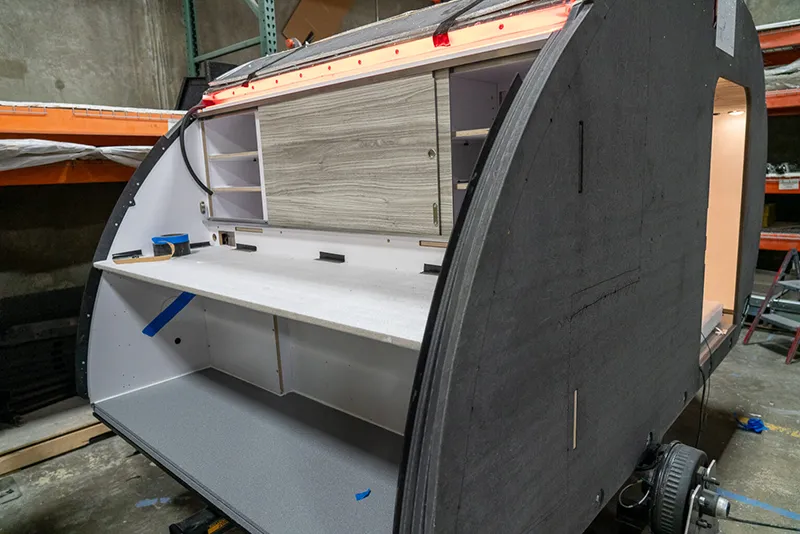

No, we are comparing aluminum to sculpted fiberglass that is pulled from a mold in the shape of the trailer. There is a huge advantage in thickness, strength and durability to a molded shell compared to a thin sheet material in fiberglass or aluminum.

If fiberglass is better for a trailer, why are most teardrop trailers built in aluminum?

It is easier. There are many times more metal shops than fiberglass shops so that expertise is more available and the barriers to entry are lower. This means you do not need as much expertise and investment in equipment to start fabricating in aluminum, so that is why it is used. In fact, it is so much easier to build in metal that the original teardrops were built at home using surplus aluminum from WWII bombers.

Is fiberglass cheaper to fabricate than aluminum?

No, fiberglass materials are more expensive, and it requires a large investment in expertise and set up.

What trailer retains its value better and last longer, fiberglass or aluminum?

With the exception of Airstream, molded fiberglass trailers such as Casita, Oliver, Scamp and Bean retain their value better than aluminum trailers. See https://campergrid.com/fiberglass-vs-aluminum-rv/ In fact, some Bean owners have been able to sell their Beans for what they bought them for or more. The average fiberglass trailer is 10-12 years old, and it will last much longer with minor care and maintenance.

Which is stronger and thicker for its relative weight, aluminum, or fiberglass?

Fiberglass. Fiberglass can be laminated and shaped to be structural without additional support. That is why our one-piece shell adds significant strength to the overall structure. The aluminum sheets typically used on teardrop trailers are flimsy and do not have the inherent structural strength of a molded fiberglass shell.

Which is more dent resistant?

Fiberglass. Fiberglass will flex and not dent under significant impact. (see our YouTube videos where we attack Bean with a sledgehammer). Aluminum dents very easily. That is why aluminum trailers are notorious for hail damage.

Which one is a better insulator, aluminum or fiberglass?

This one is easy, fiberglass. Aluminum is a great conductor of heat and cold. It is so good it is used in heat sinks to quickly transfer heat. In fact, you would be hard pressed to find a better exterior material to transfer heat and cold into your trailer than aluminum. The exception is clear anodized aluminum like an Airstream which reflects heat with its mirrored finish. Fiberglass is a great insulator and that is why it is used to make insulation! In fact, you probably have fiberglass insulation in your home keeping you warm in the winter and cool in the summer. Do you want an exterior skin that inherently transfers heat and cold into your trailer or insulates from it?

Which has more flexibility from a design standpoint?

When it comes to design flexibility and artistry, fiberglass wins by a long shot. We could not have sculpted Bean to win a design award if we fabricated it in aluminum. More importantly, you can mold fiberglass into a strong structural shape like the Bean dome with no roof seams to leak water. Without extremely expensive stamping machines or artisans, aluminum is limited to how you can fold it or bend it. That typically means you will have a seam where the roof and side walls meet and that means risking exposure to roof leaks.

Which material is better to paint if you want to minimize paint chips?

You guessed it, fiberglass! The non-porous surface of aluminum is a terrible surface to bond paint. That is why you must introduce primers, scuffing and etching to get them to bond. Fiberglass and paint are molecularly similar, so they love each other and form a much stronger bond. Better paint adhesion means less risk of paint chips or even peeling. This is particularly important when you consider all the debris your tires are going to fling at your trailer’s paint job!

Is the finish on a fiberglass or aluminum trailer more UV resistant?

The base material (aluminum or fiberglass) has nothing to do with the durability of the finish. The durability of the finish has everything to do with the quality of the paints and gelcoats you use. When it comes to UV resistance, you get what you pay for. We use expensive automotive grade paints and the best UV resistant marine grade gelcoats on Bean.

Corrosion and chemical resistance?

Aluminum is good, but fiberglass is better. That is why so many industrial storage tanks are made of fiberglass.

Ease of repair if it gets damaged?

This one is a tie. We repair both the same way with typical bodywork (Bondo and paint). Most body shops can repair fiberglass damage to your trailer and if they will not, a boat shop can easily do so.

What is more sustainable and energy efficient?

Aluminum is very abundant but fiberglass is even more so. From this stand point fiberglass is sustainable because the main ingredient in fiberglass is glass and glass is made from sand, an abundant, natural, non-depleting resource. The more durable a trailer, the longer it will last and the less need for disposal. Less disposal means less waste and more sustainability. Fiberglass trailers last longer than aluminum trailers.

Fiberglass is known for its very low embodied energy – the total energy required to produce a product from the raw materials stage through the delivery of fiberglass products. In comparison, aluminum extraction requires an excessive amount of electricity. The joke about aluminum is that it is “congealed electricity” https://theconversation.com/the-trouble-with-aluminium-7245 . Shockingly, 3% of the world’s entire energy supply goes to aluminum extractions!

Why is aluminum referred to as "congealed electricity"?

So much electrical energy is required to produce aluminum that it is almost as if aluminum were solidified electricity.

Which material expands and contracts (thermal expansion) more with temperature changes and should I care?

Aluminum expands and contracts more with temperature changes and, yes, you should care if durability is important to you in a trailer. Think about it. Your trailer can experience changes in temperature that can range from below zero to plus 150 degrees when you account for radiant heat. The materials of your trailer grow and shrink with those fluctuations and those cycles create stresses on fasteners, seals, and joints. Fiberglass has one of the lowest rates (coefficients) of thermal expansion so it minimizes that stress. Aluminum has one of the highest coefficients of thermal expansion so it accentuates those stresses. Do you want a trailer with fewer seams (one-piece shell) and a material that minimizes the stresses of thermal expansion or one with more seams, more growth, and more stress with temperature changes?